When it comes to rail corridors or electrical substations, the boundaries that protect your assets are more than just physical barriers — they are critical safety features. Steel is often used in rail environments; however, as a conductive material, it requires earthing and bonding systems to ensure electrical safety. In comparison, FRP’s non-conductive properties eliminate the need for these additional safety measures, streamlining installation, and reducing associated costs.

Glass Reinforced Plastic (GRP) fencing and screening provide a non-conductive alternative to traditional steel systems. In environments where electrical infrastructure is present, GRP’s inherent non-conductivity helps reduce the risk of electrical transfer, protecting both personnel and equipment without the need for additional earthing or bonding measures.

Some applications include:

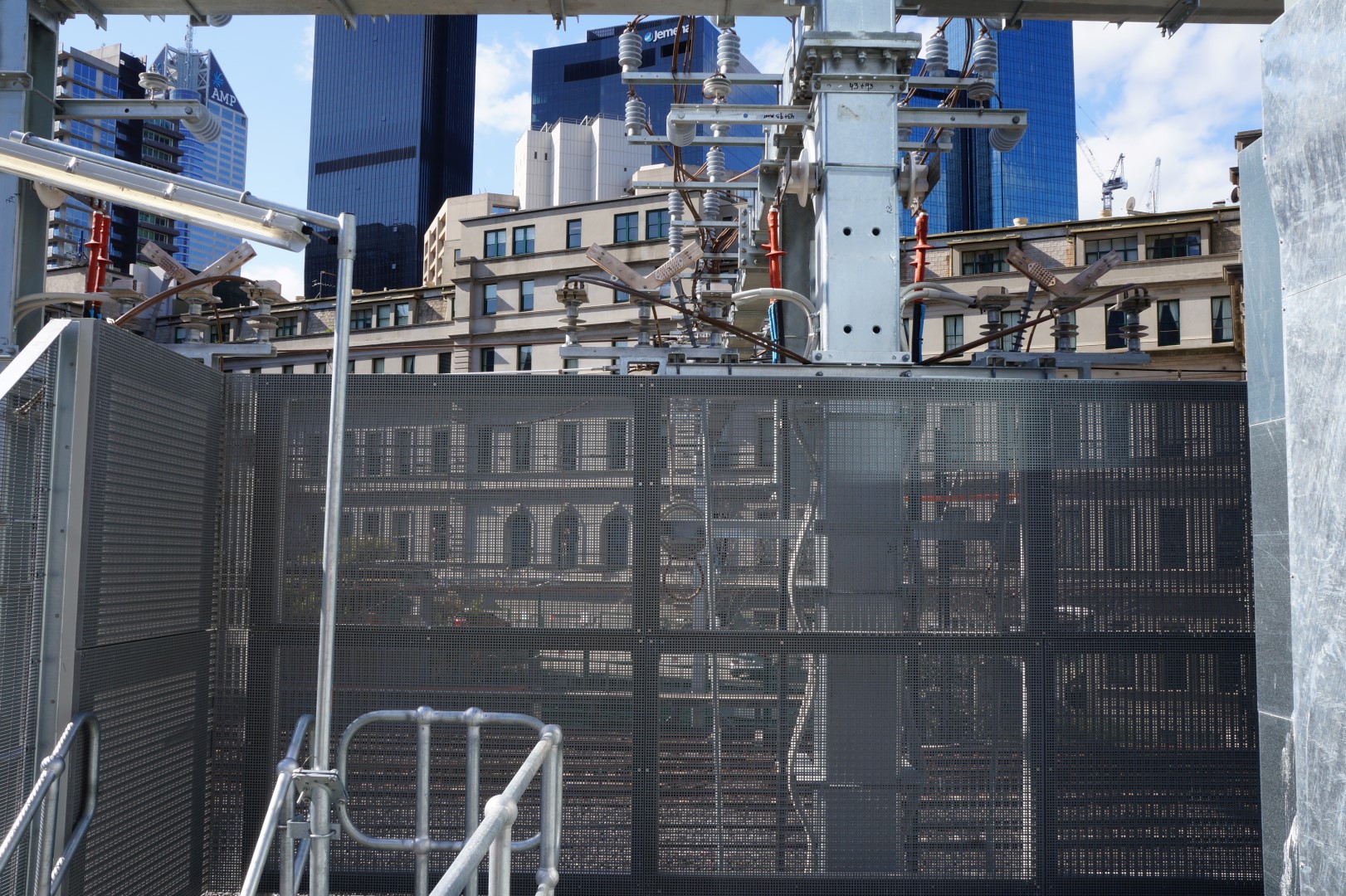

- Substation fencing – ensuring safe perimeters around live equipment.

- Rail corridor screening – providing secure boundaries without the hazards of conductive materials.

- Trackside enclosures – protecting signalling or control equipment in electrified zones.

Beyond safety, GRP fencing and screening also bring long-term advantages:

- Corrosion resistance – no rust, no decay, even in harsh weather.

- Durability – structures stay secure and reliable for decades.

- Low maintenance – no repainting, anti-rust treatments, or frequent replacements needed.

For rail and electrical engineers, the case is clear: GRP offers all-around protection while eliminating the risks conductive materials introduce. In environments where safety can’t be compromised, GRP isn’t just an alternative — it’s the ideal solution.

UK

UK

NZ

NZ

AU

AU